HR4-10 High Production Automatic Clay Interlocking Brick Machine Soil Interlocking Brick Machine Lego Brick Machine

Product Description

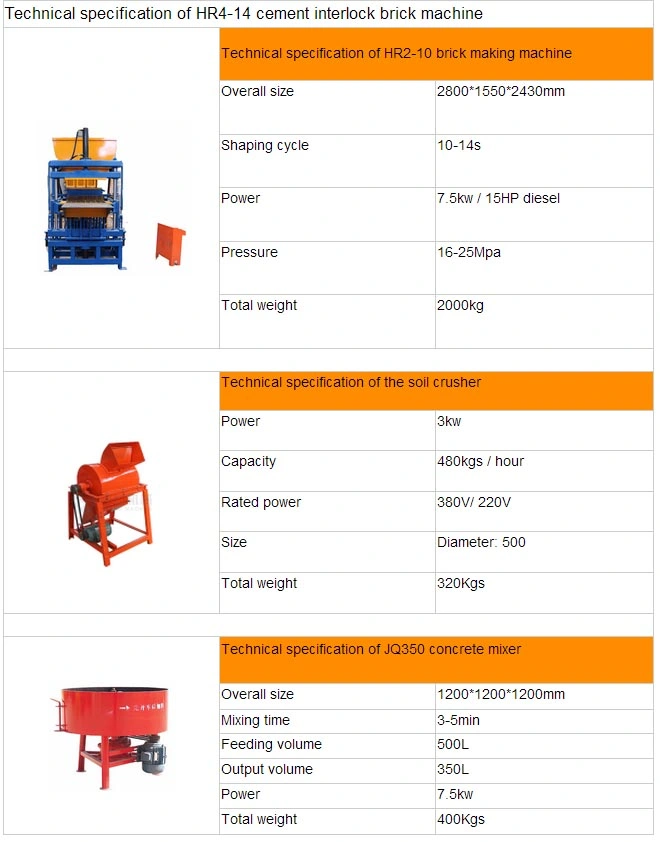

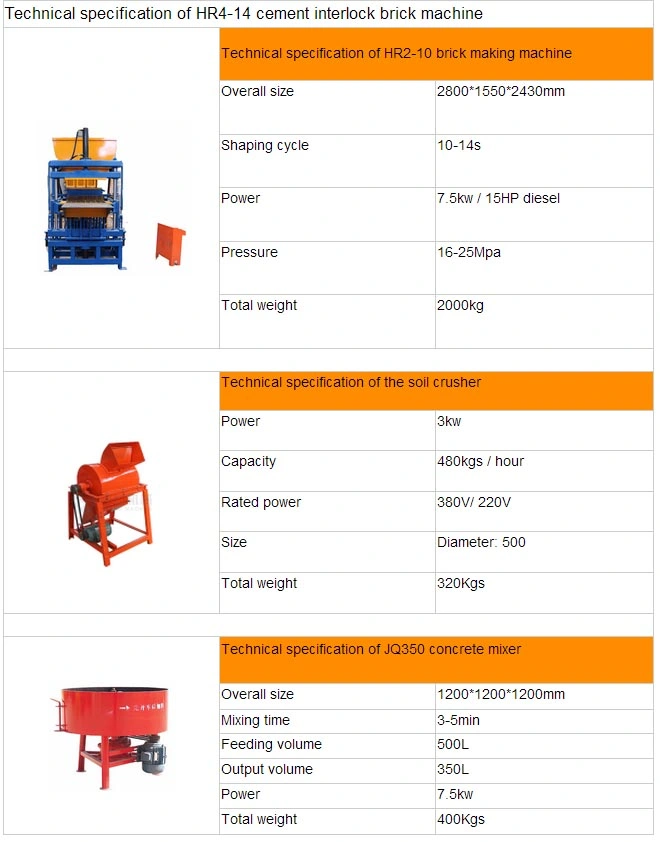

Our soil ,clay, fly ash lego interlocking brick making machine has two versions,diesel engine power and electricity motor version.They have same capacity and function.The diesel engine power version is particular designed for somewhere lack of electricrty .Both of them can produce different size and style of bricks by changing moulds.

The advantages of HR4-10 High Production Automatic Clay Interlocking Brick Machine Soil Interlocking Brick Machine Lego Brick Machine

1. Automatic brick machine. PLC controlled, Very easy to operate.

2. 4 brick would be made in less than 10 sedonds.

3. Brick height can be changed.

4. 4-10 can make different size of clay brick blocks and pavers by changing mould.

5. Double oil cylinder makes the brick much more strong.

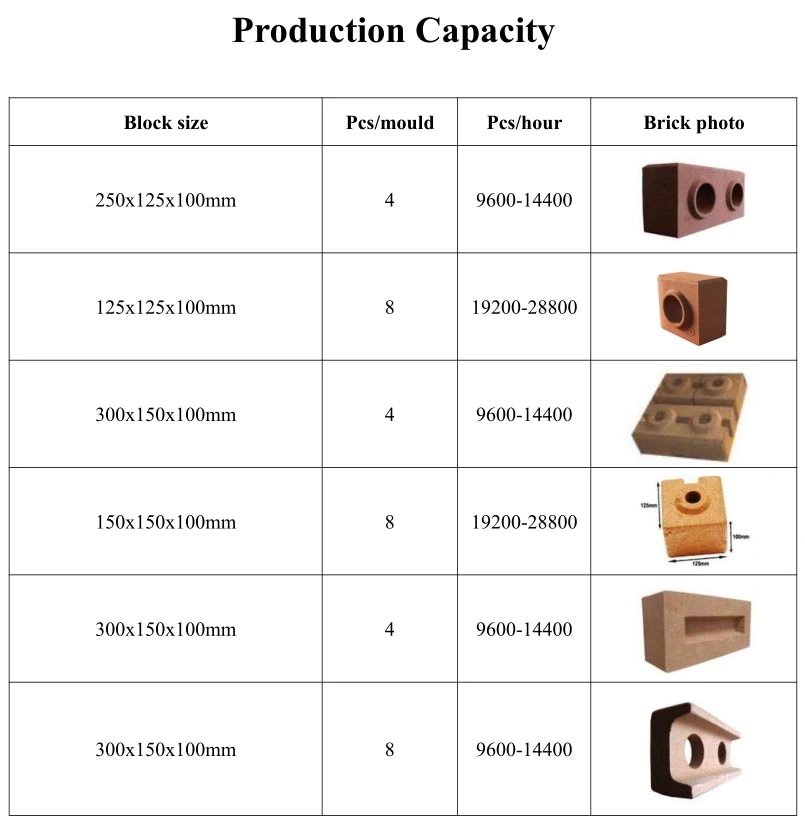

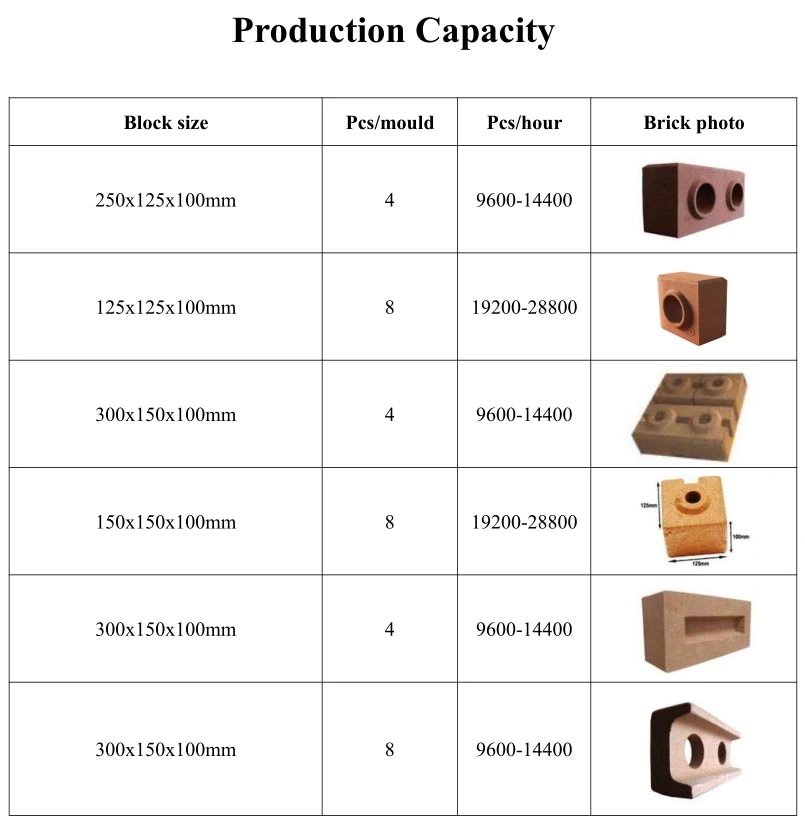

Production of HR4-10 High Production Automatic Clay Interlocking Brick Machine Soil Interlocking Brick Machine Lego Brick Machine

Company profile

Our sevice

we have go big after sale service team , they are all the experience

technician , over 20 workers have the passport ,they all have the oversea

experience.

So we not only have good service in the pre service , we also think highly

of the after sale service.

Pre-sale:

(1) Professional suggestions (raw material matching, machine selection, plan

The condition of building factory, feasibility analysis for brick machine production line)

(2) Device model choice (recommend the best machine according to the raw material, capacity

and the size of brick)

(3) 24 hours on-line service

(4) Welcome to visit our factory and production line any time, if you need, we can Make invitation

letter for you.

(5) Introduce the company file, product categories and production process.

Sale:

(1) Update the production scheduling in time

(2) Quality supervision

(3) Product acceptance

(4) Shipping on time

After-sale:

(1) The engineer will guide to carry out the plant at the clients side if needed.

(2) Set up, fix, and operate

(3) offer training to the operator until they are satisfied at clients side.

(4) Skill support the whole using life.

(5) Recall clients regularly ,get feedback in time ,keep well communication with each other

CONTACT INFORMATION

Product Description

Our soil ,clay, fly ash lego interlocking brick making machine has two versions,diesel engine power and electricity motor version.They have same capacity and function.The diesel engine power version is particular designed for somewhere lack of electricrty .Both of them can produce different size and style of bricks by changing moulds.

The advantages of HR4-10 High Production Automatic Clay Interlocking Brick Machine Soil Interlocking Brick Machine Lego Brick Machine

1. Automatic brick machine. PLC controlled, Very easy to operate.

2. 4 brick would be made in less than 10 sedonds.

3. Brick height can be changed.

4. 4-10 can make different size of clay brick blocks and pavers by changing mould.

5. Double oil cylinder makes the brick much more strong.

Features of HR4-10 High Production Automatic Clay Interlocking Brick Machine Soil Interlocking Brick Machine Lego Brick Machine

1.We adopt top brand elements, like Siemens motor, Schneider switches and so on.

2.We adopt carbonized and heat treated, making moulds more stable and wear-resisting.

3.We adopt Air cooling system, help machine work stably.

Production of HR4-10 High Production Automatic Clay Interlocking Brick Machine Soil Interlocking Brick Machine Lego Brick Machine

Company profile

Our sevice

we have go big after sale service team , they are all the experience

technician , over 20 workers have the passport ,they all have the oversea

experience.

So we not only have good service in the pre service , we also think highly

of the after sale service.

Pre-sale:

(1) Professional suggestions (raw material matching, machine selection, plan

The condition of building factory, feasibility analysis for brick machine production line)

(2) Device model choice (recommend the best machine according to the raw material, capacity

and the size of brick)

(3) 24 hours on-line service

(4) Welcome to visit our factory and production line any time, if you need, we can Make invitation

letter for you.

(5) Introduce the company file, product categories and production process.

Sale:

(1) Update the production scheduling in time

(2) Quality supervision

(3) Product acceptance

(4) Shipping on time

After-sale:

(1) The engineer will guide to carry out the plant at the clients side if needed.

(2) Set up, fix, and operate

(3) offer training to the operator until they are satisfied at clients side.

(4) Skill support the whole using life.

(5) Recall clients regularly ,get feedback in time ,keep well communication with each other

CONTACT INFORMATION