Automatic Cement Block Moulding Machine Interlocking Paver Block Making Machine

QT6-12 block machine a new model based on QT6-15D, molding time for solid brick is 12s instead of 15s.

Advantages of the QT6-12 Block and Plain Bricks Molding Machine:

1. It is the newest developed models of Hollow block making machine

2. Fastest forming cycle: hollow blocks---10-12s Solid bricks: 10s

3. High efficiency: 30% higher efficiency the other similiar models

QT6-12 Technical Parameter

Advantages of the QT6-12 Block and Plain Bricks Molding Machine:

1. It is the newest developed models of Hollow block making machine

2. Fastest forming cycle: hollow blocks---10-12s Solid bricks: 10s

3. High efficiency: 30% higher efficiency the other similiar models

QT6-12 Technical Parameter

1. Overall dimension: 2500x1620x2770mm

2. Mian vibration form: Platform virbraiton

3. Vibration frequency:4800(r/min)

4. Molding cycle:12-20s

5. Overall power:34kw

6. Raw material :crushed stone, cement, cinder, slag, sand,clay,gangue, perlite,coal fly ash and other industrial wsates.

2. Mian vibration form: Platform virbraiton

3. Vibration frequency:4800(r/min)

4. Molding cycle:12-20s

5. Overall power:34kw

6. Raw material :crushed stone, cement, cinder, slag, sand,clay,gangue, perlite,coal fly ash and other industrial wsates.

QT6-12 Productivity | |||

Hollow block size | Molding cycle(s) | Qty/mold | Per 8 hours |

400*200*200 mm | 14-18s | 6 pcs | 10000 |

400*150*200 mm | 14-18s | 7 pcs | 11500 |

400*120*200 mm | 14-18s | 8 pcs | 12500 |

Other settings for production

Except for block making machine, you will also need batching machine, cement silo, mixer, conveyor belt and stacker.

Direction for use

1. Raw material feeding. After mixing cement, sand, water, quarry etc, material will be delivered in to hopper via conveyor belt.

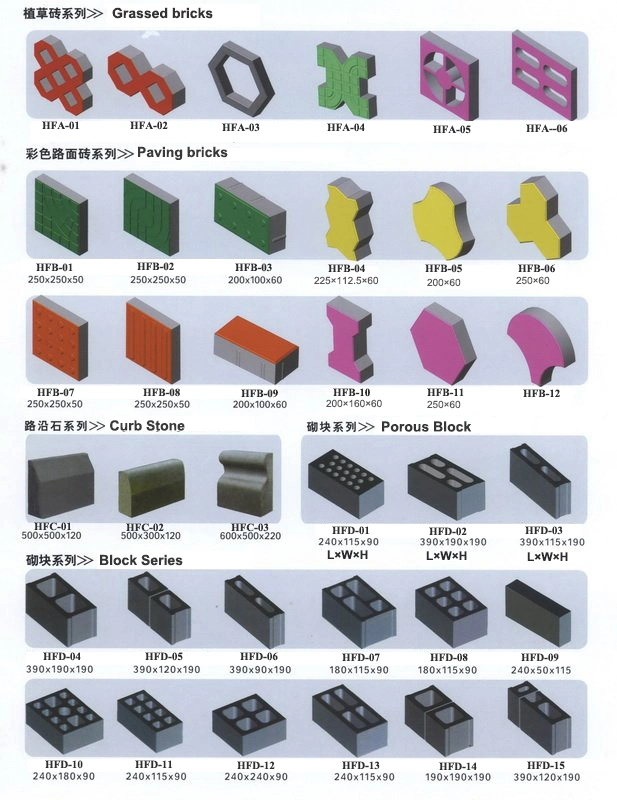

Block Samples2. Up mold goes to back, and raw material falls down from hopper, after feeding, up mold fall down then platform start to vibrate for molding.

3. Block conveyor will convey blocks after molding, use trolley to take it to curing area.

Our Services

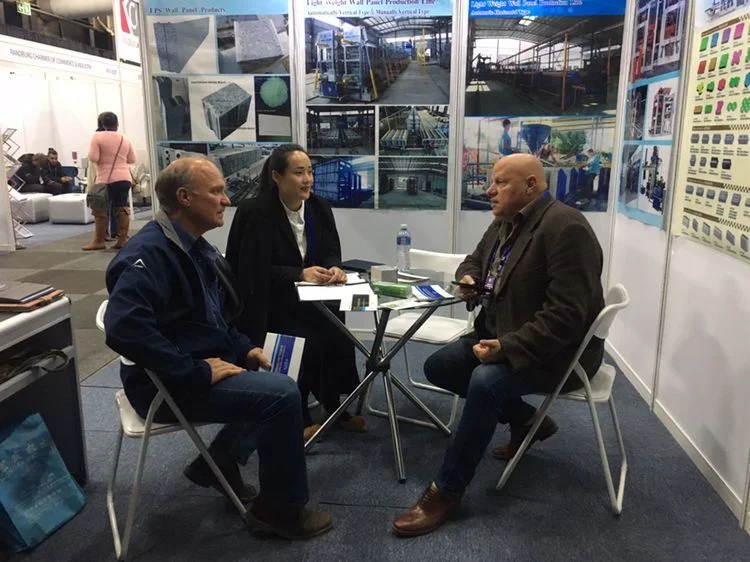

Pre-sales technical support

According to each customer's demand and budget, we offer you the professional solution, process flow design and production equipment. More importantly, we welcome every customer to visit our factory and working machine in the site before placing the order. We will arrange cars, hotels and translators for the visiting customers.

After-sales technical support

Assist clients to finish the factory planning. Before delivery equipment to customers, complete debugging and checking. Provide a full instruction manual for the whole system. Provide technical guidance for the installation and use of the unit, including installation advice and electrical connection.

Packing&Shipping

Packing&Shipping

Certifications

FAQ

FAQ

1. Can this machine make my brick or other size block?

We would design and do the mould according to customer's Drawing.

We would design and do the mould according to customer's Drawing.

2. Are your company is the manufacture or trading company?

We are Direct factory,not agent or trading company,and the quality and after-sale services is quaranteed.

We are Direct factory,not agent or trading company,and the quality and after-sale services is quaranteed.

3. How can I trust the machines quality?

Our products passed ISO9001-2000 and CE identifications, and we making machines for 27 years,with full experience, updating technical idea and application.Furthermore our machines have been exported to more than 96 countries and always have a good reputaion from our oversea customers.We will do fully test our products before shipment,make sure every equipment work well

when they come to your hand.

Our products passed ISO9001-2000 and CE identifications, and we making machines for 27 years,with full experience, updating technical idea and application.Furthermore our machines have been exported to more than 96 countries and always have a good reputaion from our oversea customers.We will do fully test our products before shipment,make sure every equipment work well

when they come to your hand.

4. When do you delivery the goods?

Normally 30 days after receipt of deposit and moulds confirmation from Buyer.

Normally 30 days after receipt of deposit and moulds confirmation from Buyer.

5. What about the payment terms?

30% as down deposit by T/T ,70% as the balance paid by T/T before loading(L/C is also acceptable).

30% as down deposit by T/T ,70% as the balance paid by T/T before loading(L/C is also acceptable).

6.Does the price include the mould?

Yes,the above price includes one set mould.

Yes,the above price includes one set mould.

7. Would you mind provide the video?

The video is available to send to you, please contact me.

The video is available to send to you, please contact me.

8.How about the commissioning of the machine and training to workers?

Yes, after finish the installation of the block production line, our engineer will do the testing and commissioning, and make the most suitable ratio of the materials to make the blocks, and train the workers how to operate and maintain the machines.

Yes, after finish the installation of the block production line, our engineer will do the testing and commissioning, and make the most suitable ratio of the materials to make the blocks, and train the workers how to operate and maintain the machines.

Company Introduction

We are a construction and building materials equipments manufacturer mainly produce all kinds of AAC block making machine,concrete mixing plant,mixer,concrete Block Shaping Machine,concrete tile making machine and concrete pipe making machine etc. with more than 29 years experience and being the biggest manufacturer in China at present.All the products are conformity with the standard of the state, and gets the ISO9001-2000 Quality System certificate, also honored as "One of the Top Ten Famous Brands of Brick &Tile field in China" and other honors.

Contact Ms. Ivy Liu | |

+86 189 3497 7386 | |

LINE ID | lineivy189 |

Address | Linyi, Shandong & Nanning, Guangxi, China |