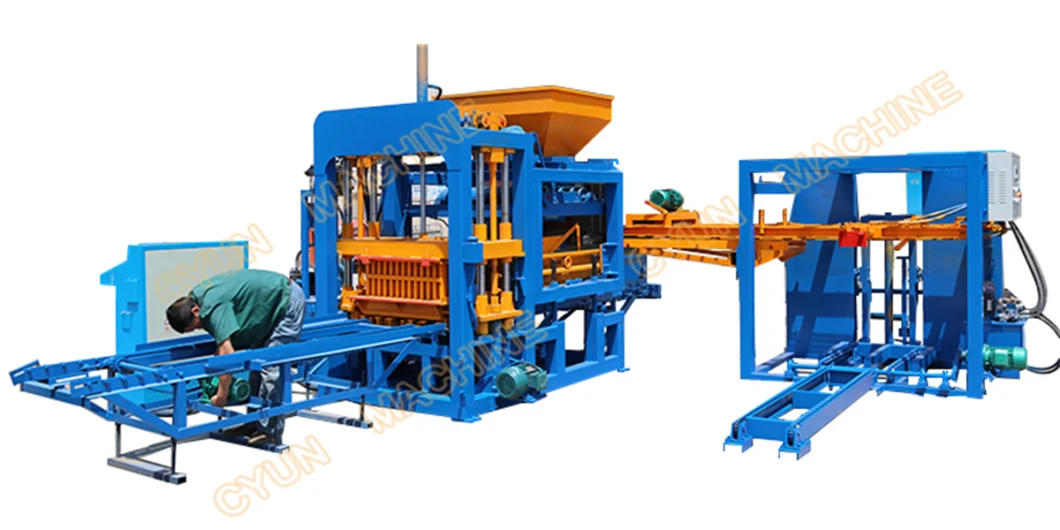

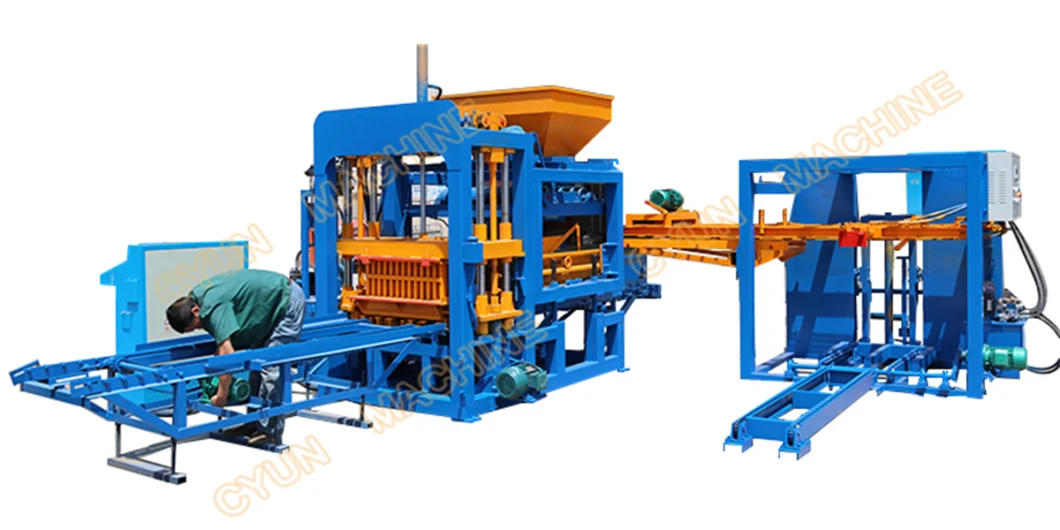

QT6-15 full automatic cement hydraulic block machine in Zambia

Machine description:

For QT6-15 block making machine, intelligence system of PLC is adopted to control, with man-machine interface and automatic diagnosis function. For the electric-hydraulic proportional valve is used in its vibrating system, the material-feeding with low frequency and the shape-vibrating with high frequency have been achieved.

Machine Advantages

A: Automatic PLC Operation, Big Capacity, Low Labour Cost

B: Hydraulic Press, High Strength of Block and Paver

C: Its material distributing system mounted with multirow of stirring forkscan,quickly and evenly discharge.

D: Produce sizes of hollow block, solid brick, hourdis, paver and curbstone by changing molds.

E: Suitable for Large and Medium-scale Block Factory

Main technical parameters

Machine details

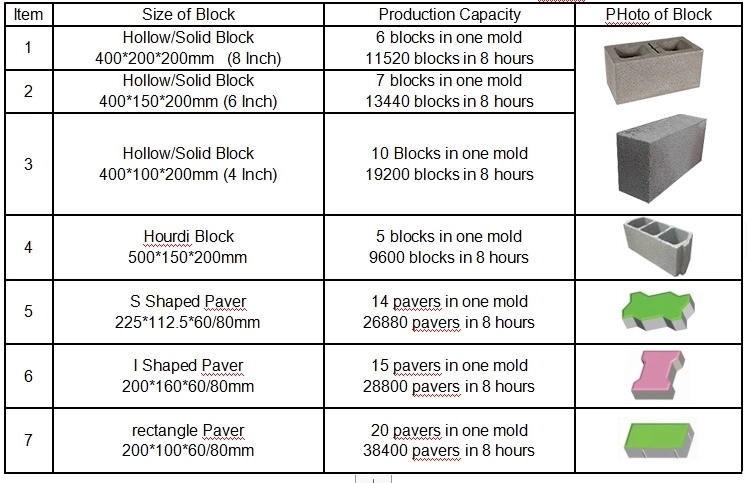

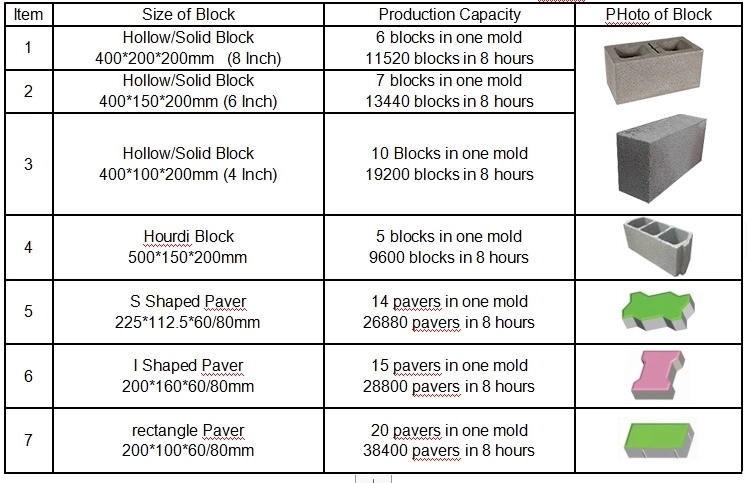

Production Capacity

Block Making Process(A→E)

Block Sample and Showing

Machine delivery and customers

About us

Our Company

Chuangyun Machinery is a professional manufacturer with 20 years history in concrete block machine and clay interlocking brick machine. Chuangyun Machinery factory is located in Linyi city, Shandong Province, China.

Chuangyun Machinery has been export to more than 100 countries, and are popular brick machine in Africa, South America, Asia because of the quality and good service.

Chuangyun Machinery will keep moving in improving quality of machine, perfecting after-sale service and developing new machines to meet various needs of customers.

Chuangyun Machinery will support customers with more and more success !

Our Service

Pre-Sale

After-Sale

FAQ:

Q1: How can i trust your machine's quality?

A: Our products have been checked and got certification ISO9001, and we have exported to many countries and regions in the world, with good reputation and quality of customer feedback. In addition, every machine is carefully tested before shipment to ensure that the machine is operating perfectly when it comes to your hand.

Q2: What about payment terms?

A: 30% Deposit before production,70% before delivery when machine is ready for shipments.

Q3: How to Cure Blocks?

A: Fresh Blocks are stacked and covered with black plastic to avoid moisture loss. The blocks are then watered daily to create a greenhouse effect, allowing the cement to harden and the blocks to strengthen. Cure your blocks for a minimum of 7 days and allow the blocks to dry to another 7 days before building. This will ensure strong good quality blocks.

Q4:How long is the delivery time?

A:20-30 days after receipt of deposit and molds confirmation from Buyer.

Machine description:

For QT6-15 block making machine, intelligence system of PLC is adopted to control, with man-machine interface and automatic diagnosis function. For the electric-hydraulic proportional valve is used in its vibrating system, the material-feeding with low frequency and the shape-vibrating with high frequency have been achieved.

Machine Advantages

A: Automatic PLC Operation, Big Capacity, Low Labour Cost

B: Hydraulic Press, High Strength of Block and Paver

C: Its material distributing system mounted with multirow of stirring forkscan,quickly and evenly discharge.

D: Produce sizes of hollow block, solid brick, hourdis, paver and curbstone by changing molds.

E: Suitable for Large and Medium-scale Block Factory

Main technical parameters

| qt 6-15 concrete block making machine cement brick making machine paver block making machine | |||

| Overall size | 3200*2300*2750mm | Power of host machine | 45KW |

| Weight of host machine | 8.35T | Vibration Force | 60-80KN |

| Pallet size | 1150*720*30mm | Vibration Frequency | Max.2800-4500 R/Min |

| Models of mixer | JS500 | Forming period | 15S-20S |

| Rated Voltage | 220V/380V | Workshop | 260M2 |

Production Capacity

Block Making Process(A→E)

| No. | Machine | Power | function |

| A | PLD800 Batching Machine | 9KW | Automatic Batching raw material |

| B | JS500 Mixer | 25.1KW | Mixing raw material with water |

| C | 6M Belt Conveyor | 0.75KW | Carry mixed material from Mixer to Block Machine |

| D | QT4-15 Block Machine | 29.7KW | Automatic material feeding system Automatic Pallet feeding system Hydraulic Station Automatic PLC Control |

| E | Automatic Stacker | 3KW | Automatically Stacking fresh Block with 4-5 pallet |

| Barrow | without | Carry Fresh Block from Stacker to Curing Sites | |

| Note: total power: 67.75KW, Electricity must be 3 phase, 50/60HZ, 380V/440V/220V | |||

Machine delivery and customers

About us

Our Company

Chuangyun Machinery is a professional manufacturer with 20 years history in concrete block machine and clay interlocking brick machine. Chuangyun Machinery factory is located in Linyi city, Shandong Province, China.

Chuangyun Machinery has been export to more than 100 countries, and are popular brick machine in Africa, South America, Asia because of the quality and good service.

Chuangyun Machinery will keep moving in improving quality of machine, perfecting after-sale service and developing new machines to meet various needs of customers.

Chuangyun Machinery will support customers with more and more success !

Our Service

Pre-Sale

- Introduce the company's basic information, product catalog and basic machine production process.

- Welcome to visit our company and products any time.If you need , we can make invitation letters for you.

- 24 hours online service.

After-Sale

- Set up, fix, and operate if buyer need.

- Provide machine-operated videos and pictures

- Send the accessories you need at any time.

- Guarantee Period: One year after installation finished at buyer's factory.

- Within one year, if the customer encounters unsolvable problems, The engineers will selectively fly to customers for local help

FAQ:

Q1: How can i trust your machine's quality?

A: Our products have been checked and got certification ISO9001, and we have exported to many countries and regions in the world, with good reputation and quality of customer feedback. In addition, every machine is carefully tested before shipment to ensure that the machine is operating perfectly when it comes to your hand.

Q2: What about payment terms?

A: 30% Deposit before production,70% before delivery when machine is ready for shipments.

Q3: How to Cure Blocks?

A: Fresh Blocks are stacked and covered with black plastic to avoid moisture loss. The blocks are then watered daily to create a greenhouse effect, allowing the cement to harden and the blocks to strengthen. Cure your blocks for a minimum of 7 days and allow the blocks to dry to another 7 days before building. This will ensure strong good quality blocks.

Q4:How long is the delivery time?

A:20-30 days after receipt of deposit and molds confirmation from Buyer.