Product Introduction

1) Fully automatic production line with high degree of automation, which can realize automatic production of feeding, mixing and forming, conveying and curing, palletizing and packing process.

2) Unique forced charging device can use various raw materials such as cement, crushed stone, slag, volcanic slag, coal ash, ceramsite, etc.

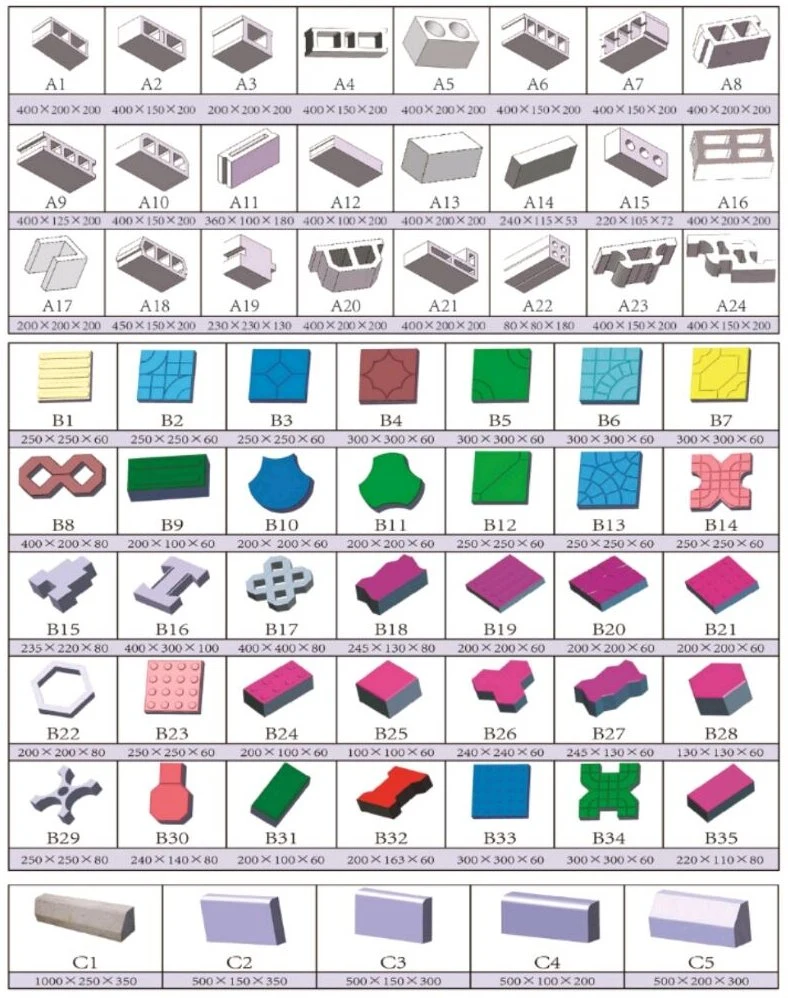

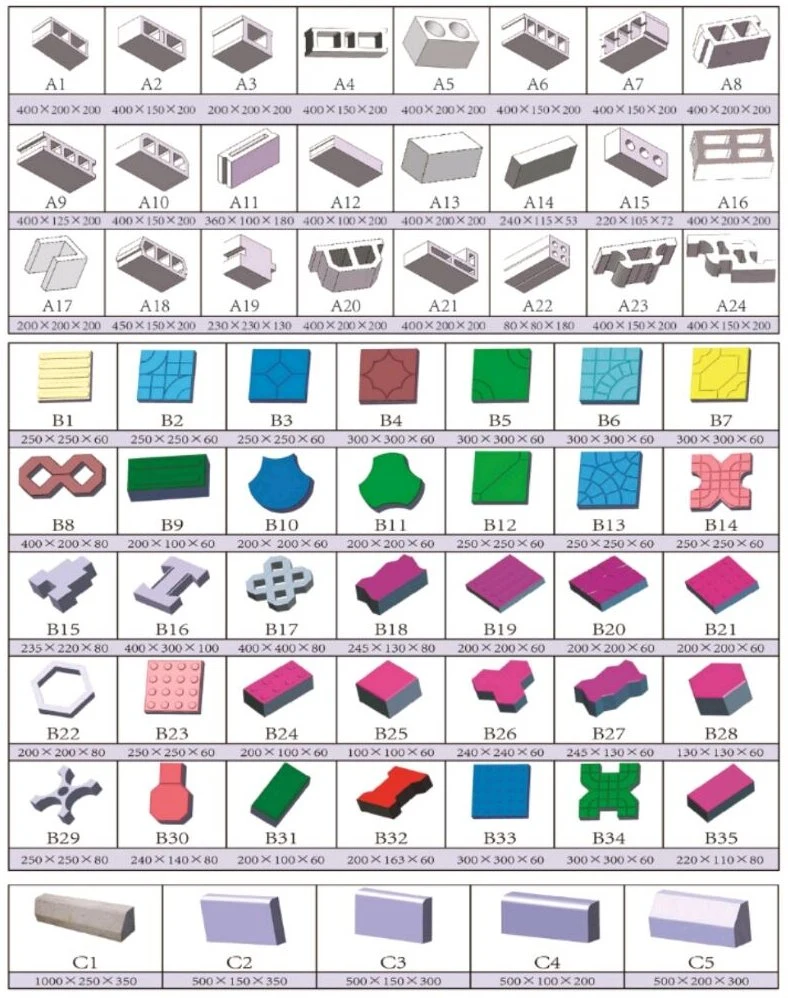

3) By changing molds can produce concrete hollow bricks, solid bricks, paver blocks, curb stones etc.

4) The cycle is 10-15s, is very short, and every time can produce 10psc (400*200*200mm) bricks.

5) Suitable for medium or large enterprises to invest in the establishment of semi-automatic or fully automatic production lines to realize automated production.

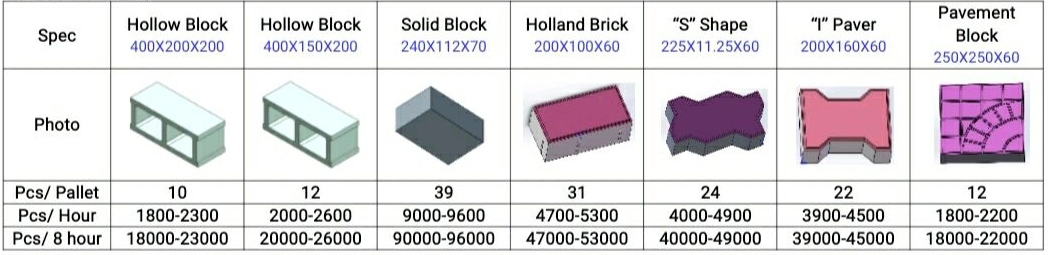

QT6-10 automatic concrete cement block making machine can product hollow blocks,solid brick, paver brick or curbstone etc. by changing molds. Here are our popular types of blocks (also can custom):

We use nude packagein container or plywood box with iron frame packing to ensure that the machines arrive at the destination in good condition.

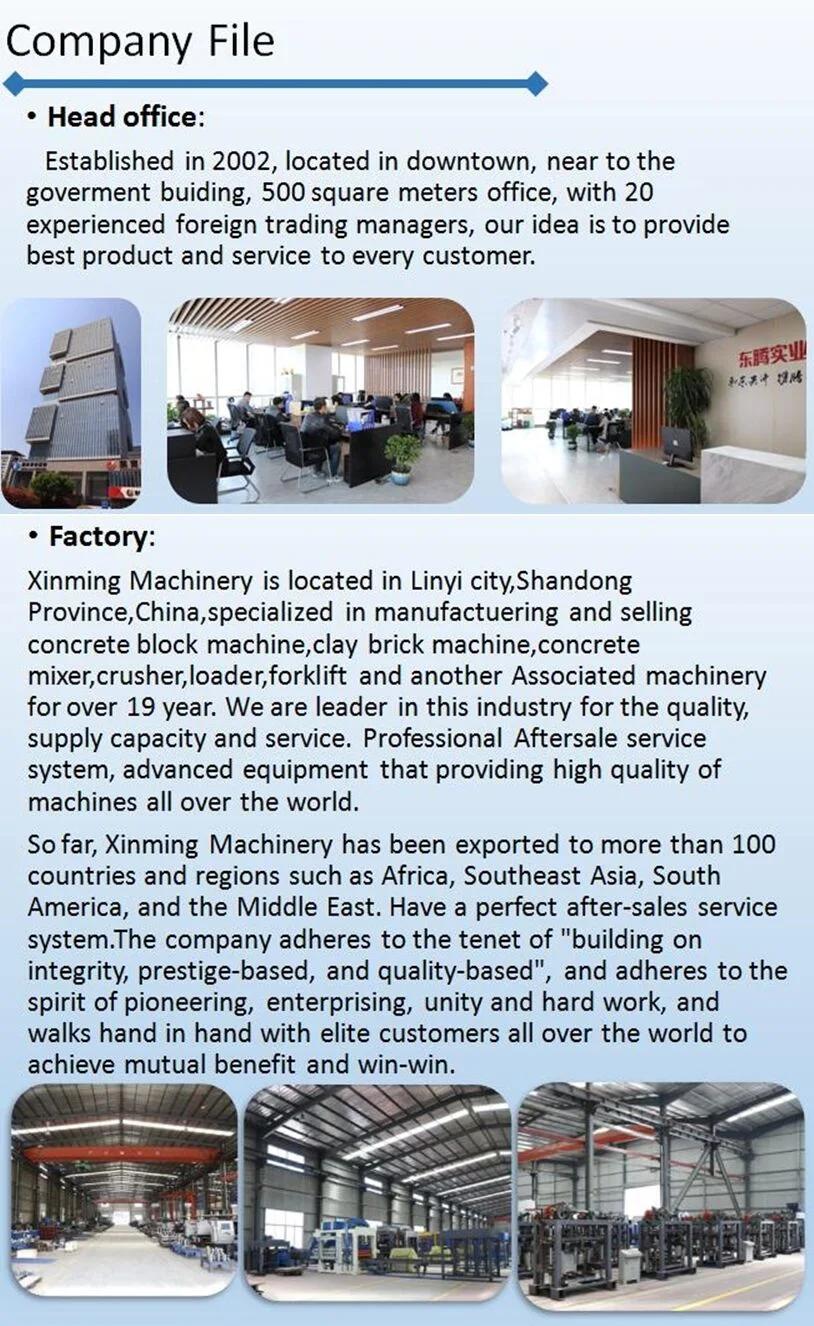

Company Description

Contact us!

Below is our contact information, please contact us. We can send you many machine working videos by mobile. We can talk further.

Thank you for your support and trust!

Export company: ShanDong Maiwoden Ioport and Export co.,ltd.

Add: Tancheng Industrial Area, Linyi City, Shandong , China

Welocone to come to visit our factory!

| QT 10-15 Huge Fully Automatic Concrete Block Making Machine |

1) Fully automatic production line with high degree of automation, which can realize automatic production of feeding, mixing and forming, conveying and curing, palletizing and packing process.

2) Unique forced charging device can use various raw materials such as cement, crushed stone, slag, volcanic slag, coal ash, ceramsite, etc.

3) By changing molds can produce concrete hollow bricks, solid bricks, paver blocks, curb stones etc.

4) The cycle is 10-15s, is very short, and every time can produce 10psc (400*200*200mm) bricks.

5) Suitable for medium or large enterprises to invest in the establishment of semi-automatic or fully automatic production lines to realize automated production.

| Machine Parameter |

| Power | 50.2 KW |

| Cycle | 10-15 S |

| Weight | 7000 KG |

| Pressure | 21 Mpa |

| Method | Vibration & Hydraulic |

| Pallet Size | 1150*900*27 mm |

| Over All Dimension | 5700*2150*2650 mm |

| Detail Introduction |

Name: PLC Control system

Function: Control the operation of the brick making machine: feeding, shaking, pressing, sending and other operating instructions.

Advantages: Programmable Logic Controller, intelligent control system, easy to operate.

Function: Control the operation of the brick making machine: feeding, shaking, pressing, sending and other operating instructions.

Advantages: Programmable Logic Controller, intelligent control system, easy to operate.

Name: Mold

Function: Used as a model to produce various styles of bricks.

Advantages: After heat treatment, not easy to rust, adopting carburizing technology, makes the mold more wear-resistant and longer service life.

Function: Used as a model to produce various styles of bricks.

Advantages: After heat treatment, not easy to rust, adopting carburizing technology, makes the mold more wear-resistant and longer service life.

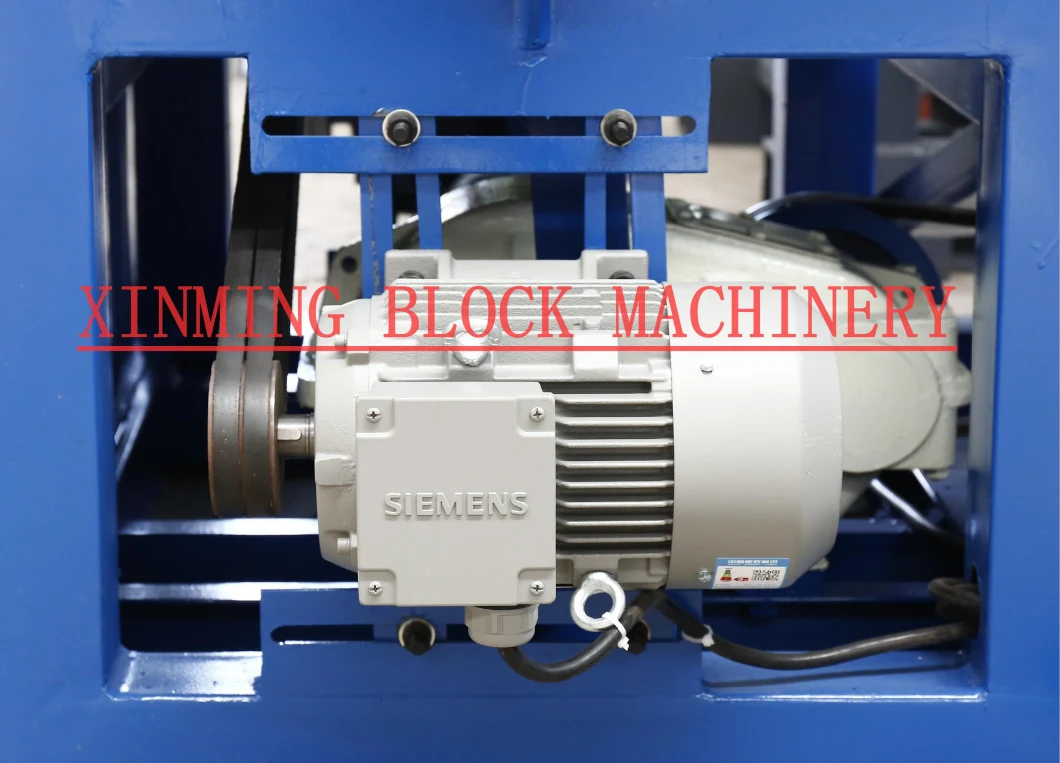

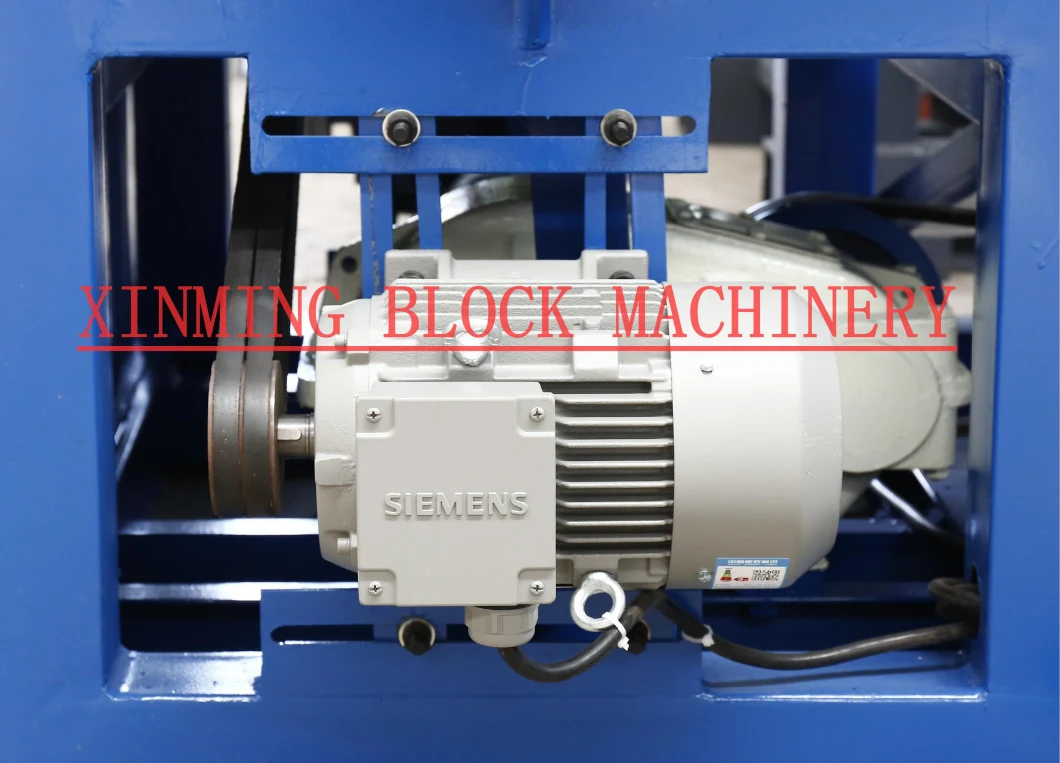

Name: Electrical Motor

Function: Provide electrical support for the operation of the machine.

Advantages: Using Simens Motor variable frequency motor, can start frequently, does not damage the machine, and also saves electricity.

Function: Provide electrical support for the operation of the machine.

Advantages: Using Simens Motor variable frequency motor, can start frequently, does not damage the machine, and also saves electricity.

Name: Laser Cuting

Fuction: Cut the materials needed to make machines.

Advantages: Use laser cutting and numerial cintrol technology, making the cutting surface of material smoother and the size more accurate.

Fuction: Cut the materials needed to make machines.

Advantages: Use laser cutting and numerial cintrol technology, making the cutting surface of material smoother and the size more accurate.

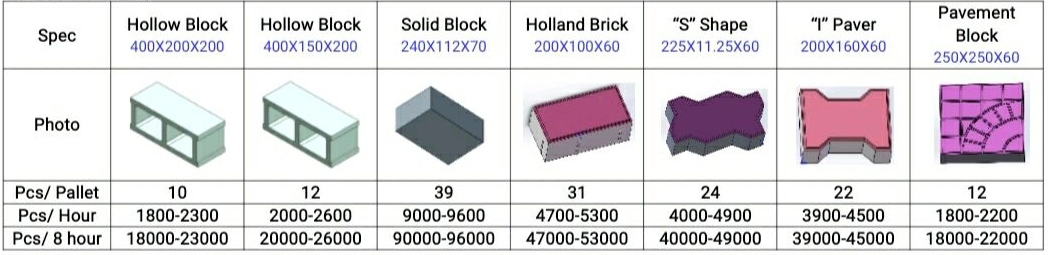

| Theoretical Production Capacity: |

| Sample Display |

| Finished Product Display |

| Packing & Delivery |

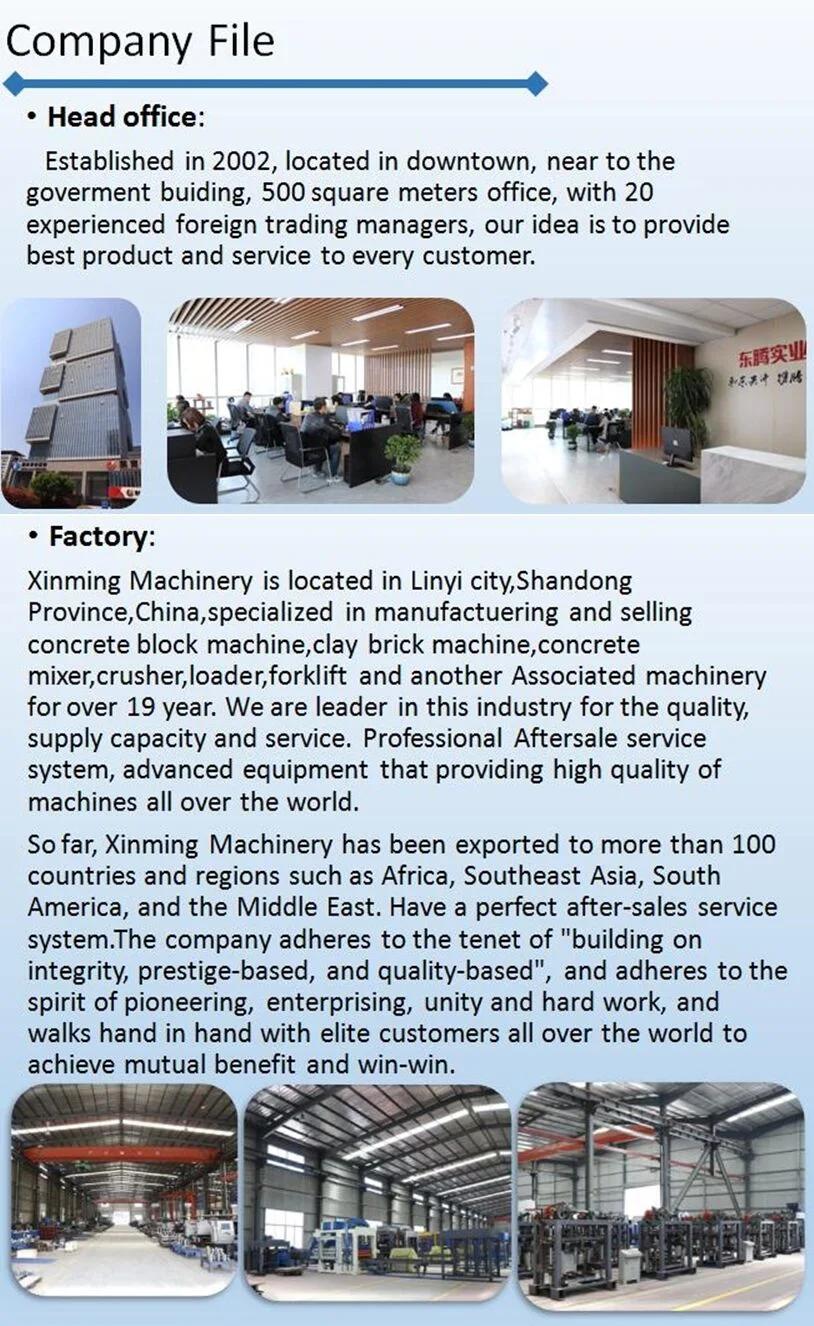

Company Description

Contact us!

Below is our contact information, please contact us. We can send you many machine working videos by mobile. We can talk further.

Thank you for your support and trust!

Export company: ShanDong Maiwoden Ioport and Export co.,ltd.

Add: Tancheng Industrial Area, Linyi City, Shandong , China

Welocone to come to visit our factory!