Advantages of QMR2-40 Small Size Manual Soil Interlocking Brick Machine Lego Brick Making Machine

1) The cheapest block machine in the world.

2) It can make different style of soil interlocking bricks by changing molds.

3) It does not need electricity, which isgood for block makers in the village .

4) It needs few labor power, even the child can press it easily.

5)Machine is detachable, which can reduce package volumn and save freight cost.

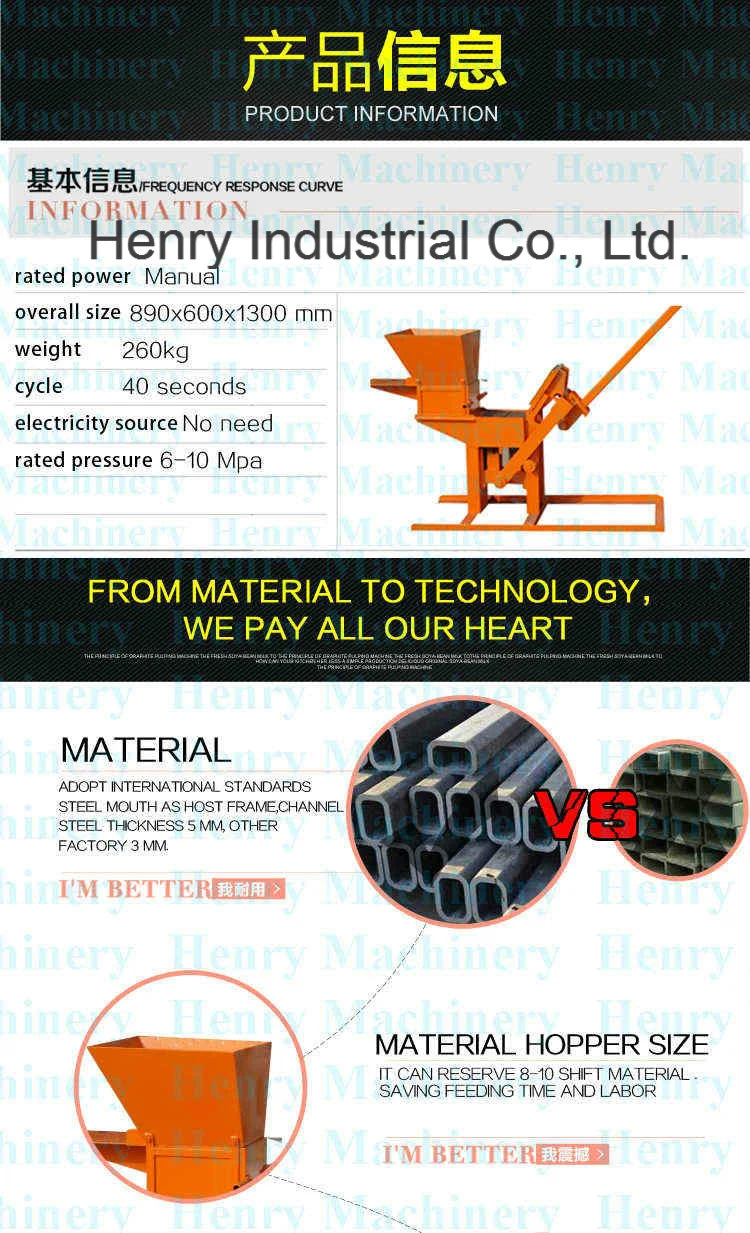

QMR2-40 Small Size Manual Soil Interlocking Brick Machine Lego Brick Making Machine Specification

| rated power | Manual |

| overall size | 890x600x1300 mm |

| weight | 260kg |

| cycle | 40 seconds |

| electricity source | No need |

| rated pressure | 6 Mpa |

Description of details of HR1-30 clay interlocking brick making machine

Theoretical production capacity

| brick size | pcs/mould | pcs/hour | pcs/8hour |

| 300*150*100mm | 1 | 120 | 960 |

| 150*150*100mm | 2 | 240 | 1920 |

| 250*125*75mm | 1 | 120 | 960 |

| 125*125*75mm | 2 | 240 | 1920 |

Bricks designed by QMR2-40

QMR2-40 block machine:

1)Material hopper size.It can reserve 8-10 shift material.Sving feeding time

and labor.

2)Material hopper with screw to be connected in order to Disassemble

quickly

3)Molding box.With screw to be connected in order to change molding more easierly

4)Off molding hook.Patent design,saving time and labor

5"Longer arm.Shorten the lever stressing distance,saving labor force and

offer more bigger pressure

6)Support.It makes machine stabilized,saving client investment

7)Molding pallet.With screw to be conected in oder to change molding more easierly

NOTICE:

1.The machine take use of steel casting molds,which are made by carburizing technology and heat treatment process,can enhance resistance ofthe mold ,prolong the cycle life, and can keep the size of the brickconstant. you canproduce various size of brick by replacing molds, it is easy to use.

2.The machine is added with a track, bearing can move along the orbit,in this way can save much labor.

Company profile

Our sevice

we have go big after sale service team , they are all the experience technician , over 20 workers have the passport ,

they all have the oversea experience.

So we not only have good service in the pre service , we

also think highly of the after sale service.

Pre-sale:

(1) Professional suggestions (raw material matching, machine selection, plan

The condition of building factory, feasibility analysis for brick machine production

line)

(2) Device model choice (recommend the best machine according to the raw

material, capacity and the size of brick)

(3) 24 hours on-line service

(4) Welcome to visit our factory and production line any time, if you need, we can

Make invitation letter for you.

(5) Introduce the company file, product categories and production process.

Sale:

(1) Update the production scheduling in time

(2) Quality supervision

(3) Product acceptance

(4) Shipping on time

After-sale:

(1) The engineer will guide to carry out the plant at the clients side if needed.

(2) Set up, fix, and operate

(3) offer training to the operator until they are satisfied at clients side.

(4) Skill support the whole using life.

(5) Recall clients regularly ,get feedback in time ,keep well communication with

each other

Guarantee

(1)We can supply one year guarantee period for our brick making machines,if the

client have the question ,they could call our service department number any time,

we will supply per day 24 hours service .

(2)Within one year ,if the client meet the unsolvable questions ,we could fly to client place to help.

Contact information