QT4-15 High Profit Fully Automatic Hydraulic Brick Machine Form China

Characteristic:

1) Adopt the intelligent PLC control, man-machine interface, automatic fault diagnosis, vibration system using electro-hydraulic proportional value control, to achieve a low-frequency vibration molding.

2) Install the multi-mixing fork fabric system, can quickly and evenly feed material into the mold box.

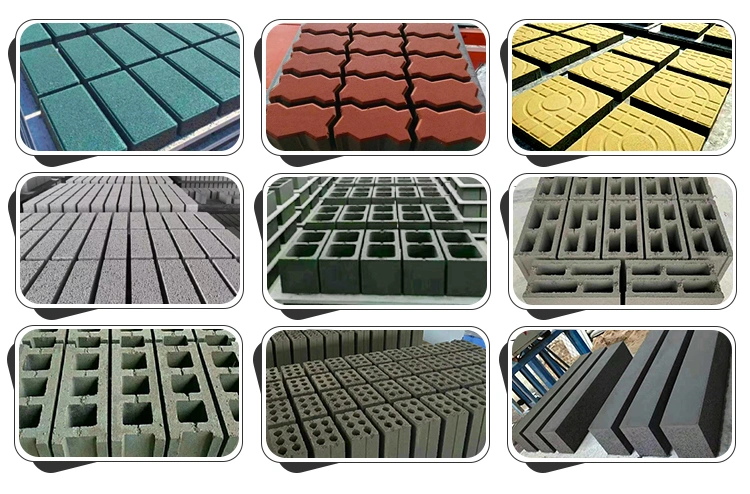

3) Can produce hollow block, solid block, paver brick, interlocking brick and so on by changing molds.

4) Storage material feeding device: by the computer control material supply, avoiding the material producing internal pressure affected by external, to ensure uniform supply, reduce error of brick strength.

5) QT4-15 is full automatic block machine, simple, easy to operation.

Main Technical Parameter:

Production line:

Optional machine section :

Production capacity:

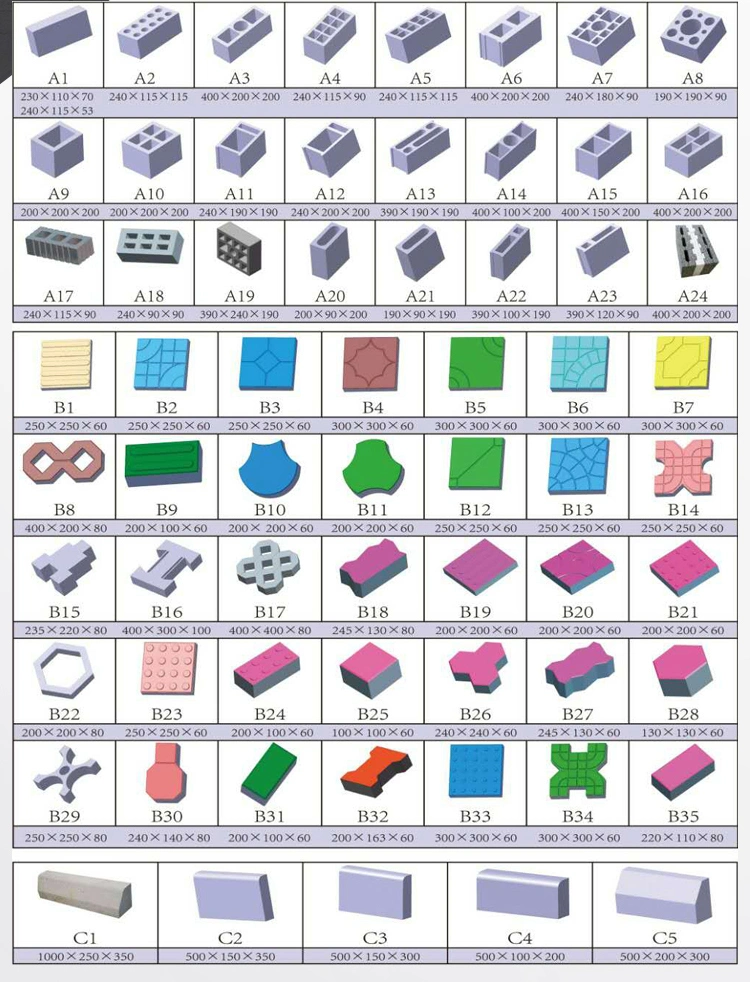

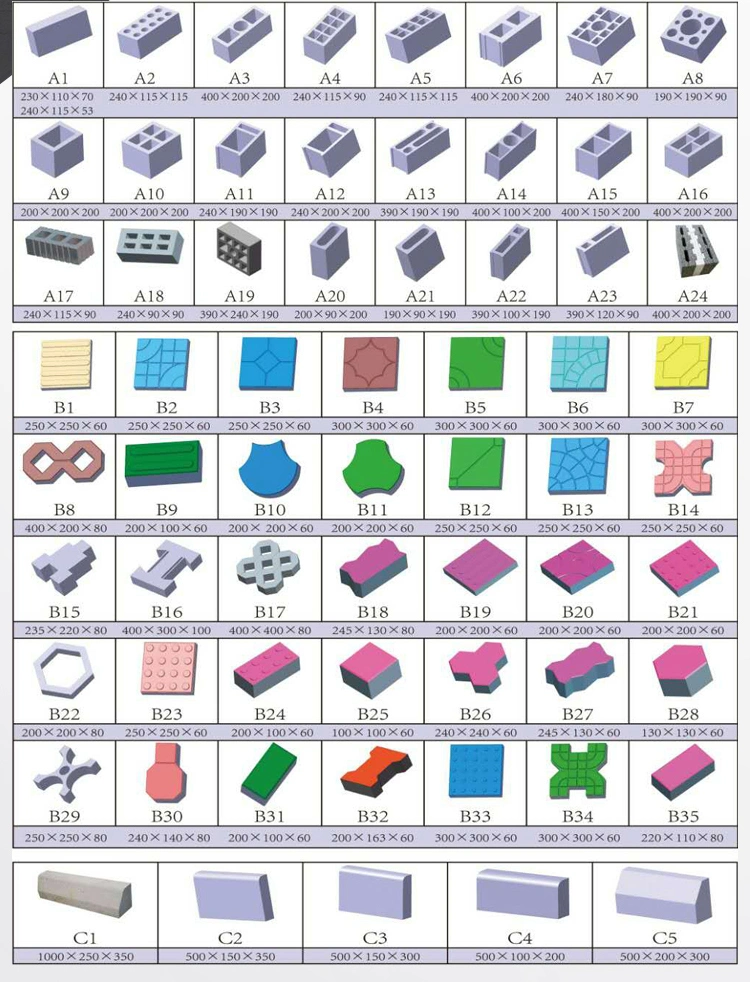

Produce different size and shape brick by changing molds.

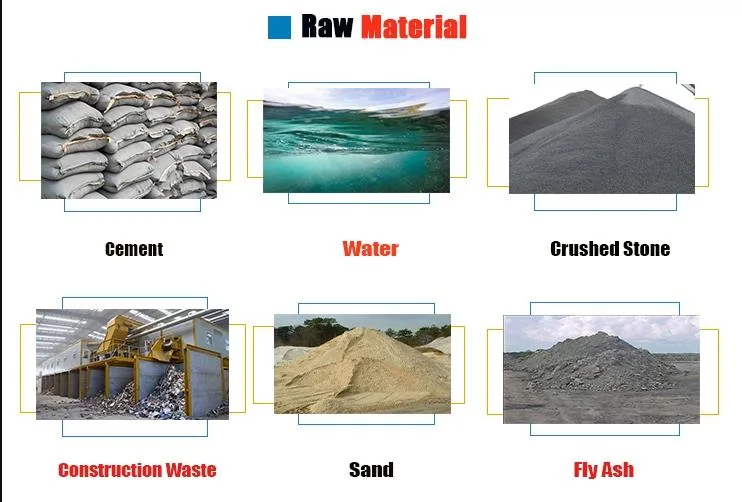

Raw material proportion:

Above information just for your reference, you could also mixer other different materials to produce bricks.

Package

Package

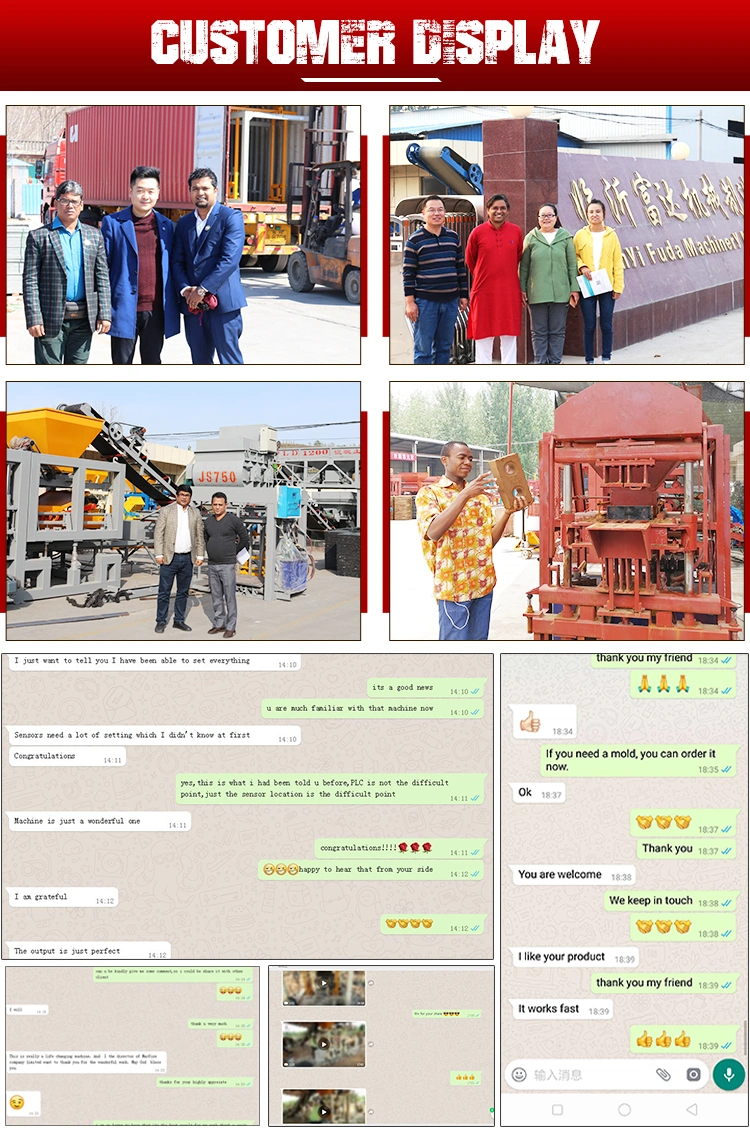

Company introduction

L

If you want to know many QT4-15 block machine information and quotation, you can contact me.

DEAN JI

Characteristic:

1) Adopt the intelligent PLC control, man-machine interface, automatic fault diagnosis, vibration system using electro-hydraulic proportional value control, to achieve a low-frequency vibration molding.

2) Install the multi-mixing fork fabric system, can quickly and evenly feed material into the mold box.

3) Can produce hollow block, solid block, paver brick, interlocking brick and so on by changing molds.

4) Storage material feeding device: by the computer control material supply, avoiding the material producing internal pressure affected by external, to ensure uniform supply, reduce error of brick strength.

5) QT4-15 is full automatic block machine, simple, easy to operation.

Main Technical Parameter:

| Host machine power | 26.45KW |

| Forming cycle | 15S |

| Vibration frequency | 4100HZ |

| Vibration force | 70KN |

| Weight | 4600KG |

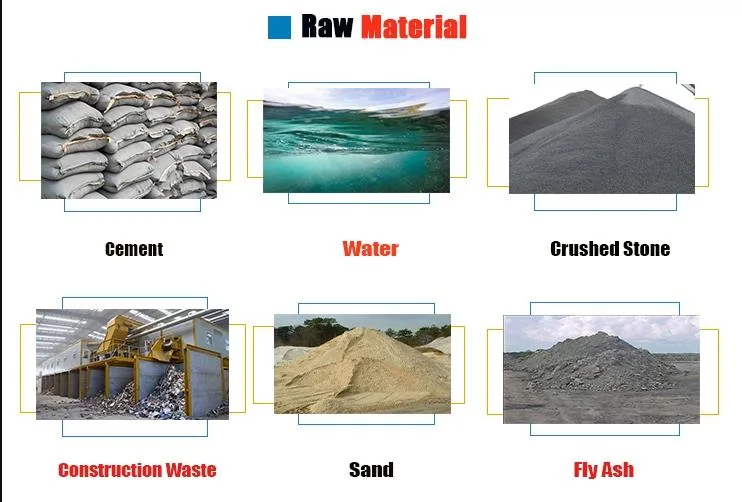

| Raw material | Concrete; Conment, Sand, Stone powder; Small stones. |

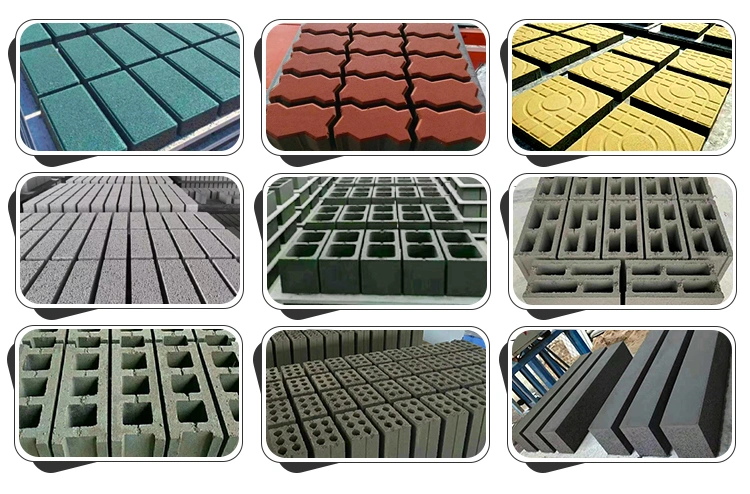

| Product brick | Hollow brick, Solid brick, Interlock block, Paver block, Curb stones and so on. |

| Pallet size | 960*550mm |

| Rated pressure | 21MPA |

| Host brick machine size | 3650(L)*2450(W)*2950(H)mm |

| Worker | 5-6 workers |

| Factory size | At least 1300m² |

Production line:

| Host Block Making Machine | Produce block |

| Mixer | JS500 , Power: 25.1KW/H |

| Conveyor | L=8M |

| Brick receiver | L=3M |

| Stacker machine | Two pallets a time stacker |

Optional machine section :

| Cement silo (Detachable) | 50 tons |

| Cement screw conveyor | L=8m |

| Wheel loader | 2 tons |

| Forklift | 3 tons |

| Automtic pallet feeding machine | |

| Color feeder machine | automatic hydraulic machine |

| Color mixer | diameter: 1.2m ,power:7.5kw |

| Conveyor | L=3m |

Production capacity:

| Brick size(L*W*H)mm | Pcs/Mold | Pcs/8Hours |

| 400*200*200mm (hollow brick) | 4 Pcs/Mold | 6800-7200Pcs/8Hours |

| 400*150*200mm (hollow brick) | 6 Pcs/Mold | 10000-11000Pcs/8Hours |

| 400*100*200mm (hollow brick) | 10 Pcs/Mold | 17000-18000 Pcs/Mold |

| 240*115*53mm (standard brick) | 26 Pcs/Mold | 44000-15000 Pcs/8Hours |

| 200*100*60mm (holland brick) | 18 Pca/Mold | 31000-32000 Pcs/8Hours |

| 200*163*60mm ("I" shape) | 12 Pcs/Mold | 20500-20700 Pcs/8 Hours |

Produce different size and shape brick by changing molds.

Raw material proportion:

| 1 | Concrete: 10% cement, 30% sand, 60% small stone |

| 2 | 10% cement, 90% stone powder |

| 3 | 10% cement, 30% fly ash, 60% stone powder |

Above information just for your reference, you could also mixer other different materials to produce bricks.

Package

Package

Company introduction

L

If you want to know many QT4-15 block machine information and quotation, you can contact me.

DEAN JI