German Technology Automatic Concrete Block Making Machine Equipment

Hawen block making machines are for the manufacture of concrete bricks, blocks and paving. The machines are manufactured to heavy-duty standards to ensure long life, high performance and the manufacture of quality products.

Company Profile:

1. Manufacturer of Block making machine with more than 15 years experience

2. ISO Certified Company

Factory Workshop

Overview of workshop for block machine

Brief Introduction

QT10-15 PC Brick making machine with motor vibration,frequency controlled.

It is mainly produce different size of hollow block,porous brick,solid brick,curb stone,paving brick,grass-pavers,tree-planted brick and slop-protected brick etc.

If top-color paving stone is required, the machine should be fitted with a face-mix device.

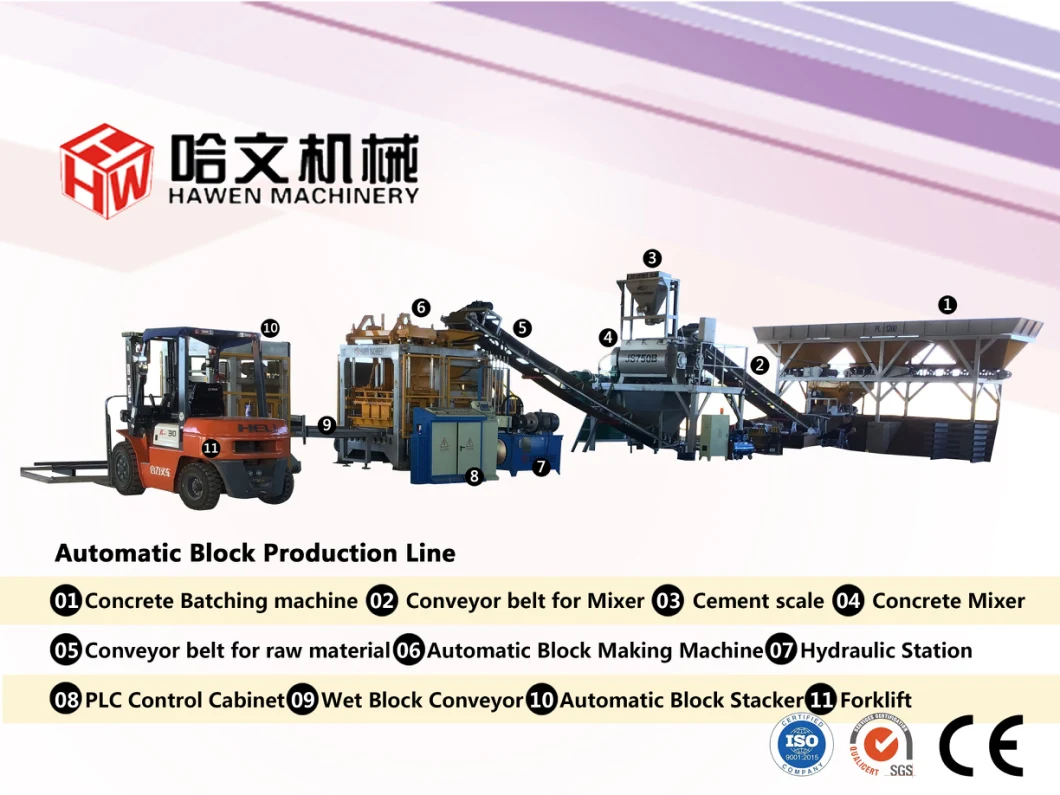

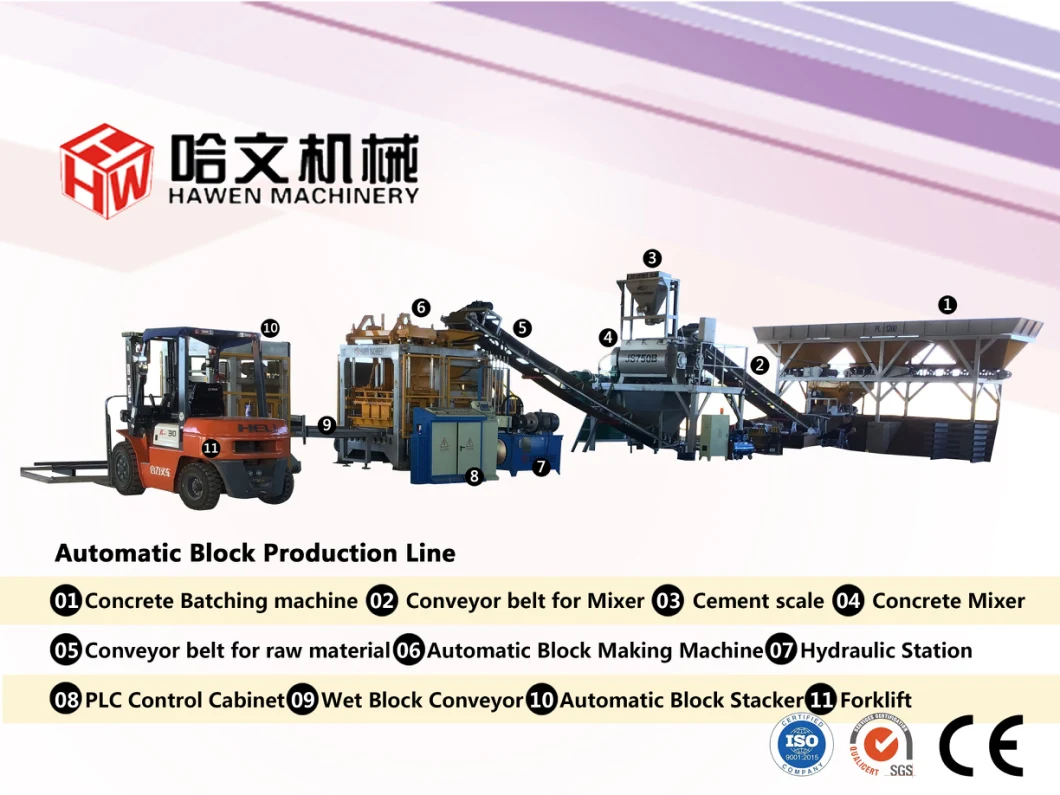

The Concrete Block making plant made by HAWEN MACHINERY are generally structured as follows:

The different required material go from the aggregate bins via transport systems to the dosing and mixing plant. It produces high-quality concrete products which is designed to meet the individual customer demands and is adapted to the available raw materials. Depending on the plant design,the concrete is then conveyoed to the block making machine. This then compacts the concrete in a mould using a combination of pressure and vibration. The fresh cocrete products go them to productions pallets via a fresh block conveyor then go to the automatic block stacker.The fresh block with pallets will be transferred by Forklift to the curing yard under the shed.In the sencond day,the dry block will be removed from the pallet by manul or by Automatic Palletizing system.

Our Control and safety systems ensure safe and fast production with minimum downtime.

The whole production line including:

Technical specification:

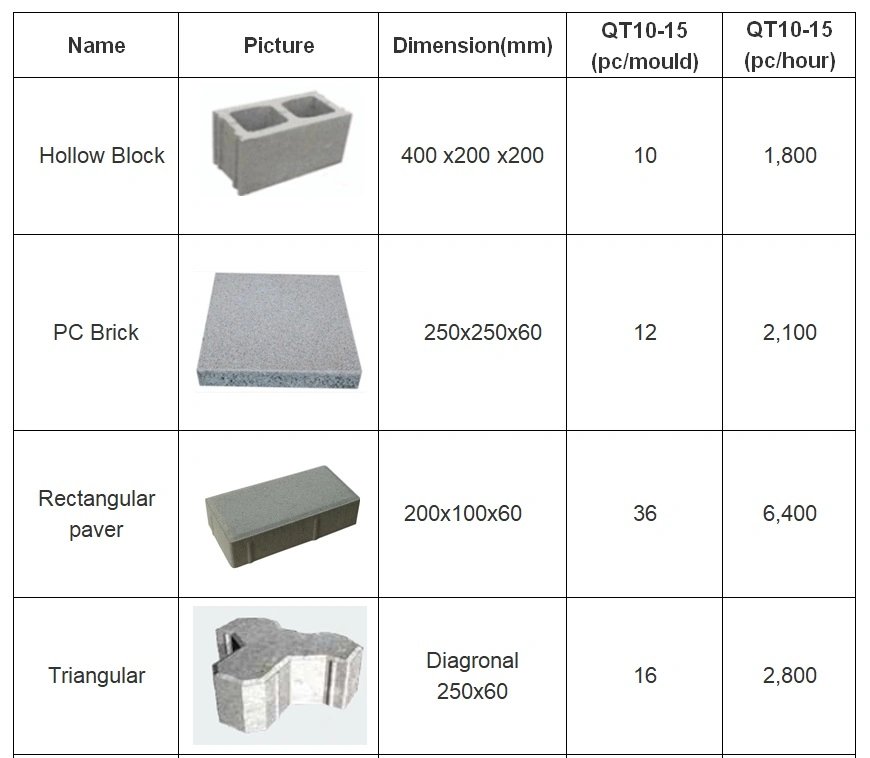

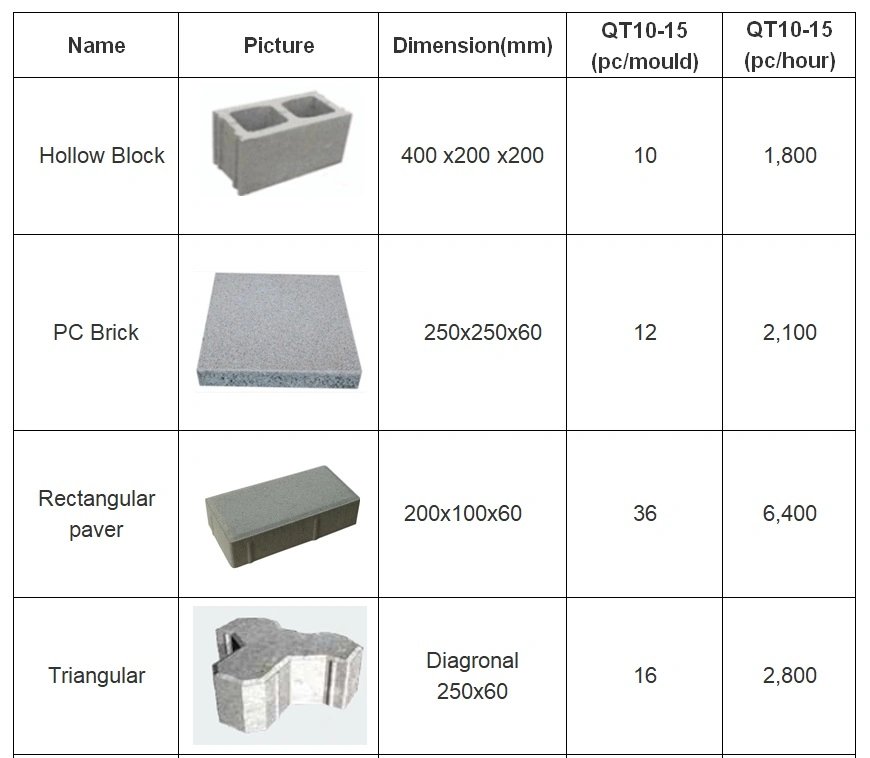

Output of QT10-15 PC Brick making machine (Pallet size 1100*950mm)

Processing equipment in the workshop

Application of QT10-15 Block Making Machine at site

with Block Stacker,Automatic Pallet Provider, automatic Pallet feeder can feed the pallet into machine automaticly.

PC Brick at site

Container loading in workshp for customers overseas

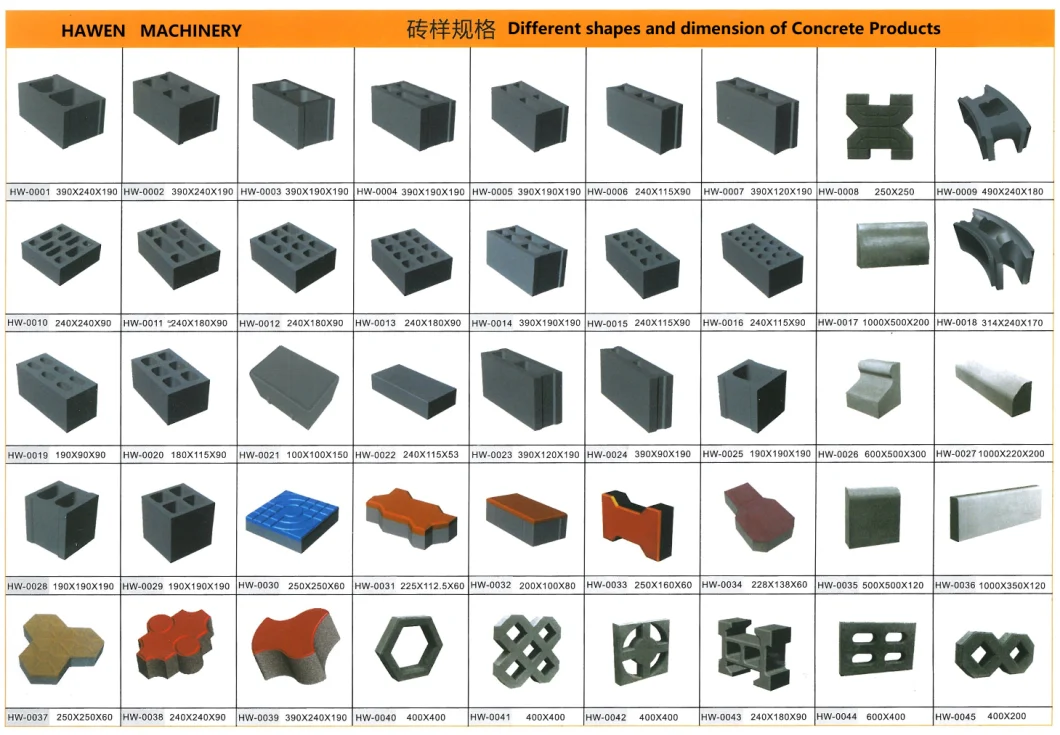

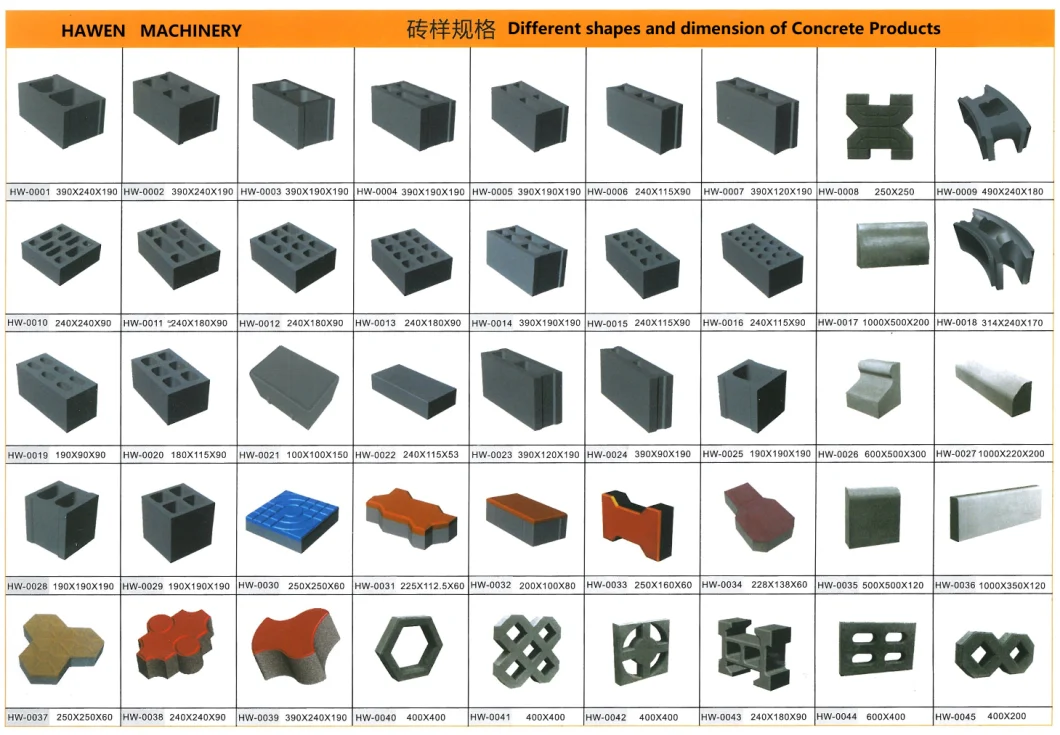

Block and Brick Sample

Our Service

Pre-sale service support

According to every customer's demand and budget, we offer the professional factory set up solution, factory layout design, process flow design. More importantly, we welcome every customer to visit our factory and visit our customer site before placing the order

Send technicians to installation site for the guidance, equipment commissioning and training. Provide high-quality spare parts thoughout the year, and the maintenance technicians are always ready to provide technical help.

Hawen block making machines are for the manufacture of concrete bricks, blocks and paving. The machines are manufactured to heavy-duty standards to ensure long life, high performance and the manufacture of quality products.

Company Profile:

1. Manufacturer of Block making machine with more than 15 years experience

2. ISO Certified Company

Factory Workshop

Overview of workshop for block machine

Brief Introduction

QT10-15 PC Brick making machine with motor vibration,frequency controlled.

It is mainly produce different size of hollow block,porous brick,solid brick,curb stone,paving brick,grass-pavers,tree-planted brick and slop-protected brick etc.

If top-color paving stone is required, the machine should be fitted with a face-mix device.

The Concrete Block making plant made by HAWEN MACHINERY are generally structured as follows:

The different required material go from the aggregate bins via transport systems to the dosing and mixing plant. It produces high-quality concrete products which is designed to meet the individual customer demands and is adapted to the available raw materials. Depending on the plant design,the concrete is then conveyoed to the block making machine. This then compacts the concrete in a mould using a combination of pressure and vibration. The fresh cocrete products go them to productions pallets via a fresh block conveyor then go to the automatic block stacker.The fresh block with pallets will be transferred by Forklift to the curing yard under the shed.In the sencond day,the dry block will be removed from the pallet by manul or by Automatic Palletizing system.

Our Control and safety systems ensure safe and fast production with minimum downtime.

The whole production line including:

- Cement silo;

- Screw Conveyor;

- Pl1200-3 Concrete Batching Machine;

- JS750 Twin-shafts Concrete Mixer;

- QT10-15 Main forming machine;

- Automatic Block Stacker.

- Automatic Pallet Provider.

Technical specification:

| Pallet size | mm | 1100×950×28 |

| Cycle time | S | 15-23 |

| Rate Pressure | Mpa | 31.5 |

| Vibration force | KN | 105 |

| Power | KW | 48.9 |

| Weight | T | 14.5 |

| Vibration frequency | r/min | 3800-4500 |

| Dimension | mm | 11500×4050×2800 |

Output of QT10-15 PC Brick making machine (Pallet size 1100*950mm)

Processing equipment in the workshop

Application of QT10-15 Block Making Machine at site

with Block Stacker,Automatic Pallet Provider, automatic Pallet feeder can feed the pallet into machine automaticly.

PC Brick at site

Container loading in workshp for customers overseas

Block and Brick Sample

Our Service

Pre-sale service support

According to every customer's demand and budget, we offer the professional factory set up solution, factory layout design, process flow design. More importantly, we welcome every customer to visit our factory and visit our customer site before placing the order